Ac Current Motor

ac current motor

Power Range and Performance

Power Output: These motors are available in a wide range of power, from a few watts for small household appliances to several kilowatts for heavy industrial applications. The power selection depends on the actual needs, for example, low-power motors are suitable for household appliances such as washing machines and air conditioners, while high-power motors are used in industrial machinery and production line equipment. The adjustable power output of the motor can provide precise power support according to the needs of different applications, and this flexibility makes it perform well in a variety of environments. High-power motors are particularly suitable for industrial equipment that needs to run for a long time and withstand heavy loads, ensuring the stability and production efficiency of the equipment.

Efficiency: These motors are known for their superior energy efficiency, which can effectively convert electrical energy into mechanical energy and minimize energy loss. The motor design uses advanced electromagnetic and mechanical technologies, which makes it more efficient than traditional motors when working. The high-efficiency design not only optimizes the operating performance of the motor, but also reduces power consumption, thereby reducing overall operating costs. This high-efficiency performance is particularly important, especially in equipment that runs for a long time, which can significantly reduce electricity bills and reduce environmental impact.

Electrical Specifications and Compatibility

Voltage Range: These motors are designed to support multiple voltage specifications, including 110V, 220V, and 380V. This variety of voltage options allows the motors to adapt to power standards in different regions around the world, thereby maintaining stable operation in various power environments. For example, in North America, 110V voltage is a common standard, while in Europe and Asia, 220V voltage is more common. The wide voltage range of the motor ensures its compatibility in different power systems, avoiding performance problems or equipment damage caused by voltage mismatch.

Frequency: The motor supports 50Hz or 60Hz frequencies, which can adapt to the frequency standards of different power systems around the world. 50Hz is generally applicable to most of Europe, Asia, and Africa, while 60Hz is more common in North America and some South American countries. The motor can operate stably under these different frequency conditions, avoiding unstable operation or reduced efficiency caused by frequency mismatch. The frequency adaptation design ensures the reliability of the motor in various industrial and commercial environments, providing stable power output in both high-frequency and low-frequency power systems.

Heat dissipation and cooling

Cooling system: AC current motors use two cooling systems: natural cooling and forced air cooling. Natural cooling relies on the heat sink of the motor housing to naturally dissipate heat into the environment, which is suitable for low to medium load applications. The forced air cooling system uses an external fan to increase air flow and remove heat more effectively, which is especially important for applications in high load and high temperature environments. This cooling method can significantly improve the stability of the motor under extreme working conditions and prevent overheating from affecting the performance of the motor.

Heat dissipation design: The heat dissipation design of the motor is optimized to ensure that the appropriate operating temperature is maintained during long-term operation. By installing heat sinks on the motor housing and strengthening the cooling system, the motor can effectively manage the heat during operation. Good heat dissipation design can prevent the motor from performance degradation or failure due to overheating, and extend the service life of the motor. In addition, the optimized heat dissipation design also improves the reliability of the motor under high load conditions, ensuring that it can operate efficiently in various working environments.

Technical specifications

| Specification | Details |

|---|---|

| Power Output | Ranges from 0.5 HP (approximately 373 watts) to several thousand watts, depending on the application. |

| Efficiency | Typically 85% to 90%, ensuring high energy conversion and reduced operational costs. |

| Voltage Range | Supports multiple voltages: 110V, 220V, 380V AC. Suitable for various global power standards. |

| Frequency | Operates at 50Hz or 60Hz, adaptable to different regional power systems. |

| Phase | Available in single-phase (for smaller applications) or three-phase (for larger, industrial applications). |

| Rated Speed | Common speeds include 1500 RPM or 3000 RPM; variable speed options available in some models. |

| Starting Torque | Designed to provide adequate torque to handle initial load conditions. |

| Running Torque | Maintains consistent torque throughout operation for stable performance. |

| Frame Size | Varies based on power rating and design; includes options for foot-mounted, flange-mounted, or pedestal-mounted configurations. |

| Weight | Ranges from a few kilograms for small motors to several hundred kilograms for larger units. |

| Cooling Type | Natural cooling for lower power applications; forced air cooling with external fans for high-load environments. |

| Temperature Rating | Insulation class typically B, F, or H, allowing operation at temperatures from 130°C to 155°C. |

| Ambient Temperature | Operates efficiently in temperatures from -20°C to 40°C; some models handle higher temperatures. |

| Housing Material | Aluminum or cast iron, chosen based on application requirements and environmental conditions. |

| Protection Rating | IP54 or IP65 ratings available for protection against dust and water ingress. |

| Bearings | High-quality sealed ball bearings, pre-lubricated for reduced maintenance and extended operational life. |

| Certifications | Compliant with international standards such as IEC, NEMA, and UL for reliability and safety. |

| Safety Features | Includes thermal protection to prevent overheating and overload protection to safeguard against excessive current. |

Application areas of this product

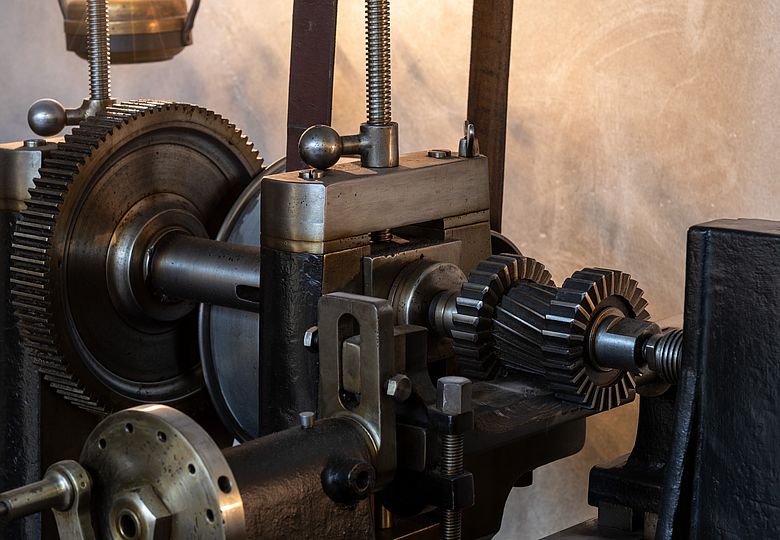

Machine Tools

Precision Machinery: AC motors are used in various machine tools, including lathes, mills, and grinders, which require precise and reliable power for cutting, shaping, and finishing metal and other materials. Their steady performance is crucial for achieving high-quality results in machining operations.

Compressor

Air and Gas Compression: AC motors drive air and gas compressors used in industrial applications to provide the necessary pressurization for pneumatic tools, refrigeration systems, and industrial processes. Their ability to handle varying loads and pressures ensures consistent and efficient operation.

Installation Method:

| Structure and installation type (IM code)) |

IM B3 | IM B8 | IM B5 | IM B6 | IM V5 | IM V1 | IM B7 | IM V6 | IM V3 |

| Installation diagram |  |

|

|

|

|

|

|

|

|

| Frame size | 63-450 | 63-160 | 63-280 | 63-160 | 63-160 | 63-450 | 63-160 | 63-160 | 63-160 |

| Structure and installation type (IM code)) |

IM V37 | IM V17 | IM B34 | IM V19 | IM V18 | IM B14 | IM V35 | IM V15 | IM B35 |

| Installation diagram |  |

|

|

|

|

|

|

|

|

| Frame size | 63-132 | 63-13 | 63-132 | 63-132 | 63-132 | 63-132 | 63-160 | 63-160 | 63-450 |

FAQ

1. What are the typical power ranges available for this motor, and how do I determine the appropriate size for my application?

The motor typically offers a wide range of power outputs, from a few watts for small, household applications to several thousand watts for heavy-duty industrial use. To determine the appropriate size, consider the power requirements of your application, including load conditions and operational demands. For instance, small appliances may only require a few hundred watts, while industrial machinery could necessitate multiple kilowatts. Calculating the required torque, speed, and operational hours will also help in selecting a motor with the right specifications.

2. What types of voltage and frequency are supported by this motor, and how does this affect its compatibility with different power systems?

The motor supports various voltage levels, typically including 110V, 220V, and 380V AC, as well as different frequencies, such as 50Hz and 60Hz. This versatility ensures compatibility with global power standards. When selecting a motor, ensure it matches the voltage and frequency specifications of your local power system. Incorrect voltage or frequency settings can lead to inefficient performance or even damage the motor, so it's crucial to check these parameters against your existing power supply.

3. How does the efficiency of this motor compare to other types, and what are the benefits of its efficiency?

This motor is designed with high efficiency, often exceeding 85-90%. Compared to less efficient models, it converts more electrical energy into mechanical energy, which reduces energy consumption and operational costs. High efficiency also translates into lower heat generation and less wear on components, potentially extending the motor's lifespan and improving overall system reliability. Efficiency is particularly important in applications where continuous operation is required, as it contributes to reduced energy bills and environmental impact.

4. What cooling methods are available for this motor, and how do they affect its performance and maintenance?

The motor can be equipped with either natural cooling or forced air cooling systems. Natural cooling relies on passive heat dissipation through the motor's outer casing, suitable for lower power applications or environments with moderate temperature. Forced air cooling involves an external fan that actively circulates air to dissipate heat, making it ideal for high-load and high-temperature conditions. Forced air cooling can help maintain optimal performance and prevent overheating, but it may require additional maintenance to ensure the cooling system remains effective.

5. Can this motor operate in harsh environments, and what protective features are available?

Yes, the motor can be designed for use in harsh environments. Options such as enhanced enclosures and high IP (Ingress Protection) ratings, such as IP54 or IP65, provide protection against dust and water ingress. Additionally, motors can be fitted with corrosion-resistant materials and treatments to withstand exposure to chemicals or extreme temperatures. When operating in challenging conditions, selecting a motor with appropriate protective features is crucial to ensure long-term reliability and performance.

6. What types of bearings are used in this motor, and how do they impact maintenance and durability?

The motor typically uses high-quality sealed ball bearings. These bearings are pre-lubricated and designed to be maintenance-free for extended periods. Sealed bearings protect against dust and contaminants, which reduces the need for frequent maintenance and extends the motor's operational life. The choice of bearings impacts the motor's smoothness of operation, noise levels, and overall durability, making it important to choose a motor with bearings suited to your specific application requirements.

7. What safety features are included with this motor, and how do they contribute to safe operation?

The motor includes several safety features such as thermal protection to prevent overheating, overload protection to guard against excessive current, and automatic shut-off mechanisms in case of fault conditions. These safety measures help prevent damage to the motor and associated equipment, reduce the risk of accidents, and ensure reliable operation. Implementing proper safety features is crucial for protecting both personnel and machinery, particularly in high-demand or hazardous environments.

Hot Tags: ac current motor, China ac current motor manufacturers, suppliers, factory, single phase motor, ac and dc machines, special motor, dual speed electric motor, ac special motor, three phase standard electric motor

You Might Also Like

Send Inquiry