Electric Miracles: The Science Of AC Vs. DC Motors

Aug 05, 2024

Leave a message

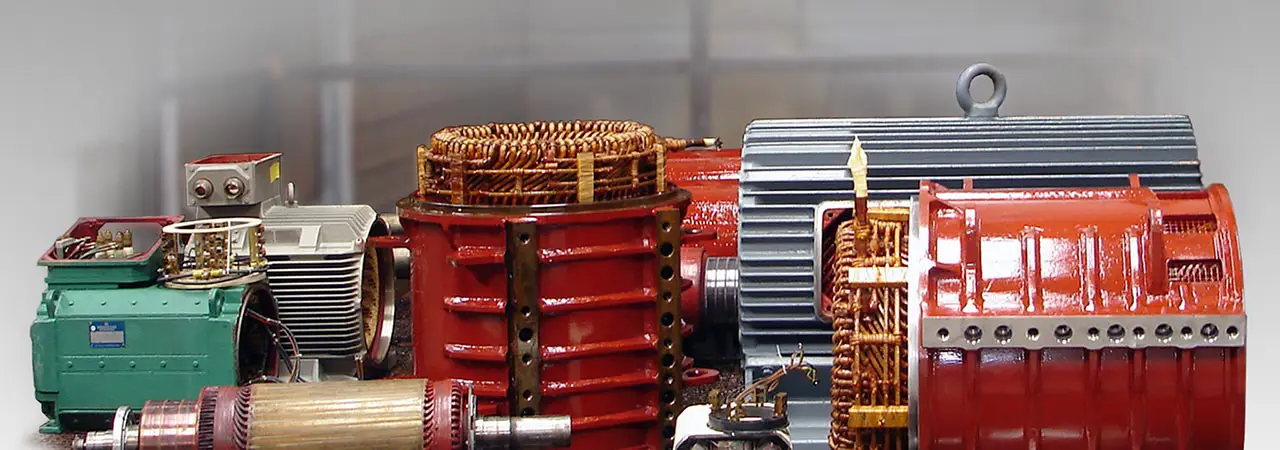

In our daily lives, electric motors are almost everywhere, whether it is household appliances, industrial equipment or electric vehicles. However, many people may not have a deep understanding of the working principles and types of electric motors. Today, we will take a deep look at the two most common types of electric motors - alternating current motors (AC motors) and direct current motors (DC motors) and how they play a vital role in modern technology. Let's unveil the mystery of these electric miracles and understand their respective advantages and applications.

Basics of AC vs. DC Motors

First, let's start with the basics of electric motors. Electric motors are devices that convert electrical energy into mechanical energy. The working principle is based on the phenomenon of electromagnetic induction. The core components of electric motors include stators (stationary parts) and rotors (rotating parts). When current passes through the stator coils, it generates a magnetic field around them. This magnetic field interacts with the conductors on the rotor to generate a rotational torque, driving the rotor to rotate.

The operating principle of AC motors is based on the rotating magnetic field of AC current. AC motors are designed to generate a stable rotating magnetic field under the drive of a constantly changing AC power supply, thereby achieving the output of mechanical energy. The following is a detailed explanation of the operation process of AC motors:

1.Formation of rotating magnetic field:

When AC current flows through the stator windings of the motor, the direction and intensity of the current change periodically. This changing current generates a rotating magnetic field in the stator. Specifically, the current of the AC power supply changes alternately in each winding of the stator, and these windings form a synchronously rotating magnetic field. The speed of the rotating magnetic field is related to the frequency of the AC power supply. For example, under an AC power supply of 50 Hz, the rotation speed of the magnetic field is about 3000 revolutions per minute (when the number of pole pairs is 2).

2.Interaction between magnetic field and rotor:

The rotor is the rotating part inside the motor. When the rotating magnetic field passes through the rotor, a current is induced inside the rotor. This is based on Faraday's law of electromagnetic induction. When the magnetic field changes through the conductor, a current is induced in the conductor. In an AC motor, this induced current creates an opposing magnetic field in the rotor. This opposing magnetic field interacts with the rotating magnetic field to generate torque, causing the rotor to rotate.

3.Speed vs. Load:

In an AC motor, the speed is determined by the speed of the rotating magnetic field. For asynchronous motors, the speed is usually slightly lower than the speed of the rotating magnetic field, and this difference is called "slip". Slip allows the motor to maintain stable operation as the load changes. For example, when the load increases, the rotor speed will drop slightly, which can provide additional torque to cope with the increased load. Synchronous motors maintain a speed that is exactly the same as the speed of the rotating magnetic field and are suitable for applications that require precise speed control.

4.Types of Motors:

Asynchronous Motor (Induction Motor): In this motor, the speed of the rotor is slightly different from the speed of the rotating magnetic field. It achieves stable operation through slip and is widely used in equipment such as fans, pumps and compressors.

Synchronous Motor: The speed of this motor is exactly the same as the speed of the rotating magnetic field. They are often used in applications that require precise control, such as generators in power systems and some high-precision mechanical equipment.

Operating principle of DC motor

DC motor is driven by DC power supply, and its current direction remains constant inside the motor. The operating principle of DC motor is based on the cooperation of brushes and commutator, which switches the current in the rotor winding to generate a stable rotation torque. The working process of DC motor is explained in detail below:

1.Current passes through brushes and commutator:

The rotor of the DC motor is connected to the power supply through brushes and commutator. The brushes are usually made of carbon material to ensure good contact with the commutator. The main function of the commutator is to periodically change the direction of the current, thereby ensuring that the direction of the magnetic field in the rotor winding changes continuously. The current flows into the commutator through the brushes and then into the rotor winding through the commutator.

2.Generation of magnetic field and rotation of the rotor:

When DC current passes through the rotor winding, a magnetic field is generated in the winding. According to Ampere's law, when current passes through a conductor, a magnetic field is generated. This magnetic field interacts with the stator magnetic field of the motor to form a torque that drives the rotor to rotate. The role of the commutator ensures that the direction of the magnetic field of the rotor continues to change during rotation, thereby maintaining the continuous rotation of the rotor.

3.Speed regulation and torque control:

The speed regulation characteristics of DC motors are one of their important advantages. By adjusting the voltage of the DC power supply, the intensity of the current can be changed to control the speed and torque of the motor. When the current increases, the intensity of the magnetic field increases, the torque increases, and the speed increases; conversely, when the current decreases, the speed decreases. This flexible speed regulation characteristic makes DC motors perform well in applications that require precise control, such as electric vehicles and power tools.

4.Types of motors:

Brushed DC motor: This motor uses brushes and commutators to achieve current switching, with a simple structure and low cost. However, the wear of the brushes and commutator may affect the performance and service life of the motor.

Brushless DC motor: This motor uses electronic commutation technology, eliminating traditional brushes and commutators. Electronic commutators drive the rotor by controlling the direction of the current, with higher efficiency, longer service life and lower maintenance requirements.

Application of advanced technology:

Modern brushless DC motors use electronic control technology, which enables the motor to achieve higher precision and efficiency during operation. For example, the application of brushless motors in electric vehicles and drones achieves precise adjustment of speed and torque through electronic control systems, improving the performance and reliability of the overall system.

Application fields of AC motors and DC motors

Alternating current motors (AC motors) are widely used in various industrial and household equipment due to their simple structure, low cost and easy maintenance. In the field of household appliances, AC motors are an indispensable power source. They drive equipment such as air conditioners, refrigerators, and washing machines. The compressors of air conditioners and refrigerators usually use AC motors, which ensure the stable operation of the equipment with their high efficiency and durability. The motor in the washing machine is used to drive the inner drum to rotate to achieve the washing and dehydration functions. Since AC motors can operate stably for a long time, they are very suitable for household appliances that need to operate reliably for a long time.

In terms of industrial equipment, AC motors also play an important role. They are widely used in key equipment such as fans, pumps, and compressors. Fans are used for ventilation and cooling, pumps are responsible for conveying liquids or gases, and compressors are used for pressurization and compression of gases. The application of AC motors in these equipment ensures the continuous and efficient operation of the production line. Especially in high-load and long-term working environments, the stability and durability of AC motors are particularly important. In addition, wind power generation also relies on AC motors to convert wind energy into electrical energy, providing green energy for the power system. Through modern technologies such as variable frequency control, the operating efficiency of AC motors has been further improved, optimizing energy utilization and energy saving.

Application fields of DC motors

Direct current motors (DC motors) are widely used in fields requiring high precision and fast response due to their excellent speed regulation performance and precise control capabilities. In electric vehicles, the speed regulation capability of DC motors enables vehicles to accelerate and brake smoothly. Electric vehicles' motors usually use brushless DC motors, which not only provide efficient power output, but also excel in energy saving and maintenance. High-precision speed and torque control enables electric vehicles to provide excellent performance under different driving conditions, improving driving experience and safety.

In the field of power tools, the flexibility and response speed of DC motors make them a power source for various tools. For example, tools such as electric drills, electric saws, and angle grinders require fast adjustment of speed and torque according to working conditions. The speed regulation capability of DC motors ensures the high efficiency of these tools in different operating modes. In addition, DC motors are also widely used in robotics. In industrial robots, DC motors provide precise motion control, supporting robots to perform complex operating tasks such as welding, handling, and assembly. Brushless DC motors improve the accuracy and reliability of robots in these applications, enabling robots to efficiently complete automated tasks. These application scenarios demonstrate the importance and advantages of DC motors in fields that require precise control and high performance.

Future Outlook

With the continuous advancement of science and technology, the technology of AC motors and DC motors is also evolving. The application of intelligent control technology has significantly improved the performance and efficiency of motors. In modern motor systems, advanced control algorithms and sensor technologies can achieve real-time monitoring and precise adjustment to optimize the operating efficiency of motors. For example, through the integrated intelligent inverter, AC motors can dynamically adjust the speed according to load requirements to achieve efficient use of energy. Similarly, the electronic control system of DC motors can also provide more detailed speed regulation capabilities and faster response speeds to adapt to different application requirements.

The requirements of energy conservation and environmental protection have promoted the development of motor technology. Future motors will pay more attention to energy efficiency and environmental performance. The use of new materials and more efficient designs will enable motors to play an important role in reducing energy consumption and reducing environmental impact. For example, the use of high-efficiency magnetic materials and low-loss designs will further improve the overall efficiency of motors. At the same time, the intelligent development of motors will promote the realization of more automated applications, such as smart home systems and smart transportation solutions, which will make motors play a more critical role in modern technology.

In short, whether it is AC motors or DC motors, they play an indispensable role in modern technology. AC motors excel in a variety of applications with their high efficiency, stability and economy, while DC motors are used in high-tech fields with their precise control and high performance. As technology continues to develop, these electric wonders will continue to lead us towards a smarter and greener future.

Send Inquiry